The cement market in Pakistan carries on to evolve amid soaring design demand from customers and financial fluctuations.

This article supplies an in-depth check out cement charge nowadays in Pakistan, price tag comparisons with preceding months, variables influencing the marketplace, and trends throughout a variety of regions. Regardless of whether you are a builder, contractor, or homeowner, knowing cement price in Pakistan is essential for budgeting and venture scheduling.

What exactly are The existing Charges?

Exactly what is the Cement Amount in Pakistan?

The cement charge in Pakistan ranges from PKR one,two hundred to PKR one,400 per 50 kg bag. This level may possibly range depending on the cement model, location, and transportation fees. Major city facilities such as Karachi, Lahore, and Islamabad are inclined to working experience somewhat larger charges as a consequence of logistical fees and greater demand for cement.

Here’s A fast overview of regular rates:

Brand name Value per fifty kg Bag (PKR)

Lucky Cement one,280

DG Cement 1,250

Fauji Cement one,230

Maple Leaf Cement 1,270

Dewan Cement one,two hundred

What Things Affect The existing Cement Costs?

Many aspects affecting cement prices Enjoy a role:

Gas & Energy Expenditures: Cement producing is Strength-intense. Fluctuations in oil and fuel rates directly influence the cost of cement in Pakistan.

Uncooked Product Availability: Crucial elements such as gypsum, clinker, and limestone have grown to be costlier, influencing the price of cement.

Seasonal Need: All through peak construction months (spring and summer time), cement need surges, elevating selling prices.

Forex Exchange Charge: Imported raw components turn into more expensive once the rupee weakens towards the greenback.

Government Insurance policies: Obligations, taxes, and import laws also influence the cement price these days in Pakistan.

These components collectively figure out how cement prices change thirty day period by month throughout Pakistan.

Cement Value in Pakistan: Comprehending the industry Developments

What exactly are the Latest Cement Price ranges in Pakistan?

The most recent cement prices in Pakistan fluctuate concerning PKR 1,200 and PKR 1,400 for each bag, affected from the brand name, length from output units, and native source chains. Cement models in Pakistan like Blessed Cement, DG Cement, and Fauji Cement sustain regular high quality, which often justifies their top quality pricing.

What Are the Predictions for Cement Rates during the Future Months?

The cement business in Pakistan is expected to stay stressed from world-wide gas charges and inflation. Analysts predict that cement rates may improve slightly or remain secure in coming months Until important adjustments arise in gasoline tariffs or raw product Value dynamics.

Variables that may affect potential pricing:

Post-election economic reforms

Gas subsidy insurance policies

World-wide commodity costs

A stabilization or reduction in fuel rates may lead to lower rates because of minimized output and logistics costs.

How Does Demand Have an effect on the Price of Cement in Pakistan?

Need for cement peaks for the duration of Energetic development seasons, for instance March as a result of September. During these durations, cement costs in Pakistan could climb as a result of limited offer and enhanced orders. Conversely, off-time months can see stabilized or a little minimized rates.

Big infrastructure and housing initiatives underway throughout cities like Lahore, Islamabad, and Karachi go on to contribute to robust cement desire, pushing the market toward bigger premiums.

Varieties of Cement Available in Pakistan: Which Really should You Choose?

What Are the Different Types of Cement Offered in Pakistan?

Pakistan offers a range of cement varieties catering to varied building assignments:

Everyday Portland Cement (OPC): The most often used sort of cement for traditional buildings.

Portland Pozzolana Cement (PPC): Gives enhanced longevity cement rate in pakistan and resistance to chemical attacks.

Slag Cement: Manufactured working with blast furnace slag, ideal for industrial structures.

White Cement: Aesthetic cement Utilized in tiles, flooring, and decoration.

Hydraulic Cement: Speedily sets when mixed with h2o, well suited for drinking water-retaining buildings.

A lot of these cement serve distinctive roles, and deciding on the correct 1 depends on development wants, environmental circumstances, and wished-for strength amounts.

Tony Danza Then & Now!

Tony Danza Then & Now! Lark Voorhies Then & Now!

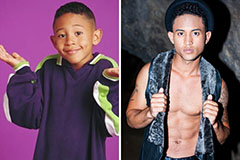

Lark Voorhies Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now!